Documentation

“A postulate is free, a promise binds”

Documented Leak Protection

Documenting our statements is important to us. We have our leak protection systems assessed by the Technological Institute so that you, as our customers, do not have to rely on us alone when we claim that our systems actually work.

Leon Buhl from the Danish Technological Institute said in 2014 that “(…) the whole exercise is completely worthless if you think you’ve secured yourself and then it’s really just a toy sitting on the wall.“

The Danish Technological Institute has established four minimum requirements for water sealing and leakage protection systems:

- Assurity of the continuous functioning of the system. This can be done by the system testing itself and connected components at regular intervals, as well as issuing an alarm in the event of a fault.

- It is possible to generate a log of events in relation to possible fluctuations in operating conditions and troubleshooting in the system.

- Detailed installation instructions and detailed operating and maintenance instructions, in accordance with the requirements of the Building Regulations, as well as instruction of the user.

- Ensuring that the plant and installation are regularly serviced so that the operational and functional capacity of the plant and installation is guaranteed, e.g. in the form of a service subscription.

At DanTaet, the four requirements are met in the following ways:

- All leak protection systems perform, at least once a day, self-tests that test all vital components.

- All leak protection systems contain event, alarm and fault logs.

- Detailed installation and operating instructions are supplied for all leak protection systems and are available on our website(link)

- All leak protection systems can be covered by a service agreement. In addition, a special guide for the inspection of residential installations has been prepared, which can be carried out by an authorised plumber.

In addition to the above, all DanTaet leak protection systems have been subject to assessment by the Danish Technological Institute so that our word is not the only claim for the functionality of the systems.

Assessment of KMP-V

Assessment of KMP-F

Assessment of UMS-F

Assessment of KMP-K

Assessment of LMI-C

Evaluation of L-PS-X

Patented technology

The core functionality of DanTaet leak protection systems is protected by a series of patents.

OptiTight ®

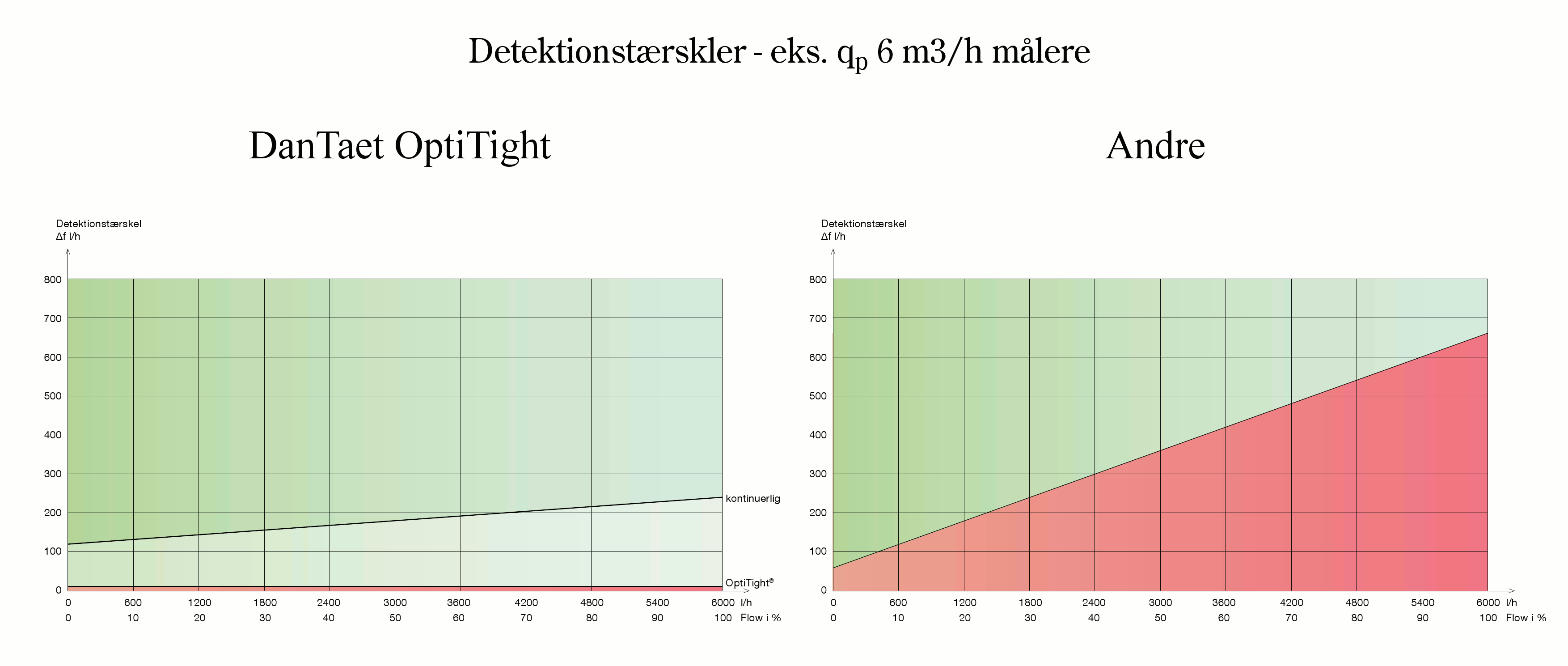

OptiTight secures district heating installations against even the smallest seepage. Using our patented method, we can detect seepages that are far below the minimum indicated values of the flows used.

You can read more about the patent here: Link

Leakage Protection of circulating hot water

A special – and patented – method is used to secure installations with circulating hot water, which means that this type of installation can also be protected.

You can read more about the patent here: Link

ALOHA ®

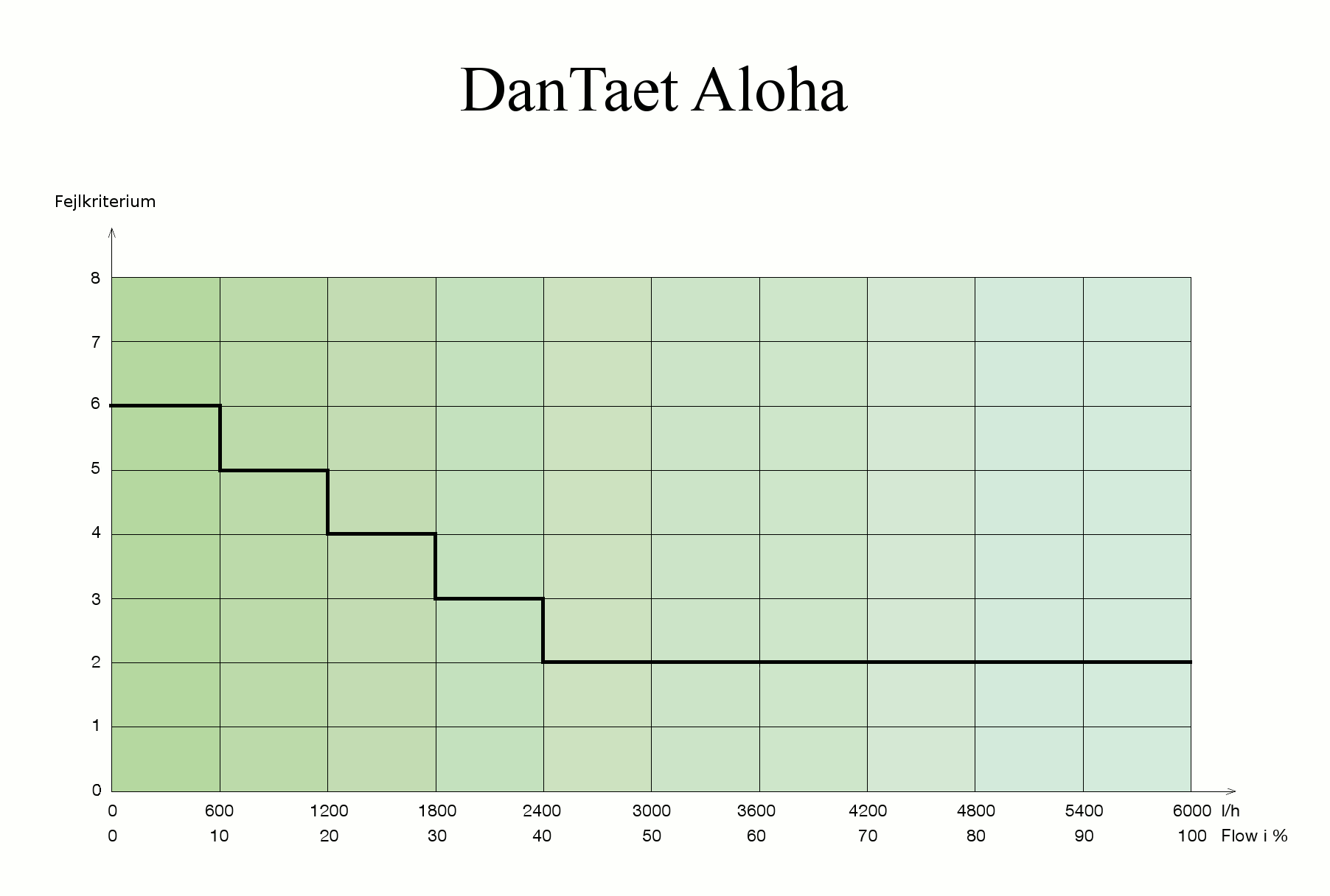

ALOHA is a mechanism for managing the passage of air bubbles through the flow meters. When a pocket of air passes through an ultrasonic meter, its sound-reflecting mirrors can be exposed, leaving the meter unable to detect a flow. This causes the display in one branch to be zero while the other branch shows a flow. Such a condition will cause the differential flow monitor to sound an alarm in a short time. ALOHA recognizes this condition and responds by raising the error criterion a number of times, delaying the alarm message to allow time for the air pocket to pass the meter. The increase of the error criterion is largest at low flows, and decreases to 0 at 25% of Qp. Air pockets are a source of many false alarms, which are effectively handled by ALOHA, thus contributing to the excellent reliability of DanTaet systems. ALOHA is patented.

You can read more about the patent here: Link

PSALM ®

The PSALM technology does not use a single counter for measuring discharge, but instead a larger number of parallel counters, each of which records consumption within a narrow flow band, and which together cover the full flow domain (spectrum). Each counter only accumulates consumption made at flows between its flow limits, and the counter is reset when the flow falls to or below its lower flow limit. The individual counters now represent columns in the flow spectrum.

Because PSALM operates with many flow bands (high selectivity), the mechanism can also be used to mitigate some of the disadvantages that a leak detector frequently faces, such as limited resolution of flow meter pulse generators, or limited update frequency for electronic flow meters.

You can read more about the patent here: Link

PIR

Especially for the protection of domestic water installations feeding built-in fire hose reels, where the installation is not equipped with ABA, DanTaet has developed – and patented – a solution where the fire hose reels are instead monitored with a PIR.

You can read more about the patent here: Link

Brass meters in stainless steel installations

The Danish Technological Institute’s pipe center instruction 027 states that “When using fittings and valves made of dezincification-resistant brass of type CW602N or equivalent, there is a high risk of stress corrosion cracking when the components are in contact with stainless steel pipes or plastic. Therefore, fittings and valves in dimensions up to 1″, where the wall thickness is low, should be made of materials that do not cause stress corrosion cracking, such as gunmetal, stainless steel or plastic.”

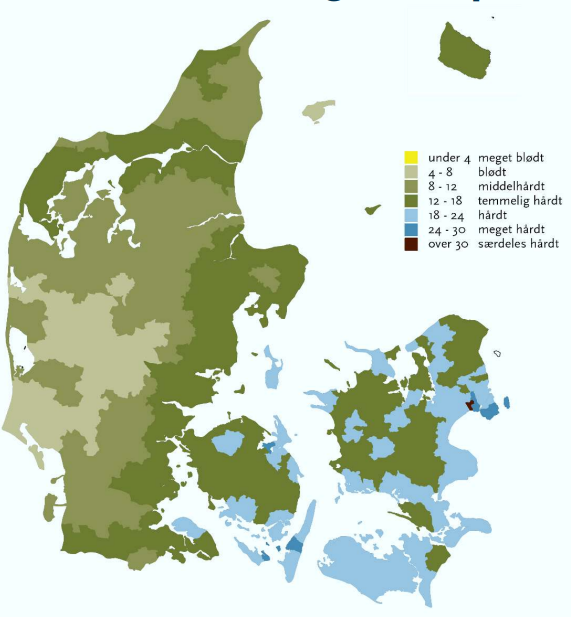

Similarly, FORCE states in the publication “New materials – new challenges” that “In risk areas, fittings made of plastic, stainless steel or gunmetal are always used.” However, the following observation is added: “The problems with corrosion of small brass valves and fittings are particularly extensive in the metropolitan area and areas with similar water quality.”. Of particular interest is the geographical delineation illustrated by the map on the right. For “other” parts of the country, it is stated that there are “no concerns in combination with plastic or stainless steel”, with the modification that it always “Depends (…) on the local water quality.”

Due to the lack of clarity in relation to water meters, which are currently most often made of brass in dimensions up to 2″, DanTaet A/S has asked the Danish Technological Institute to assess whether the above considerations about “small brass valves and fittings“ also apply to water meters made of dezincification-resistant brass.

Af The Danish Technological Institute’s assessment states that “It is (…) the Institute’s assessment that the wall thickness of water meters is normally greater than that of small fittings and small valves, just as the water-affected surface is far greater in the water meter than in small fittings and valves, and that the corrosion load must therefore be assessed to be far less.

As for water meter glands, these can be referred to as fittings. Most meter glands are normally constructed so that there is a good wall thickness in the entire fitting, which is why thecorrosion load compared to ordinary small fittings must be considered to be small.

If, despite the Danish Technological Institute’s assessment, you wish to do so, DanTaet A/S can of course supply screw connections in either plastic or gunmetal.

Fire assessment

DanTaet has therefore asked the Danish Institute for Fire and Security Engineering (DBI) to assess which technical measures can permit leak protection of supply water installations with fire hose reels. Based on DanTaet’s request, DBI has prepared an assessment of possible technical solutions they consider satisfactory.

DBI has, in general, concluded that the following override signals for the leakage protection system are to be considered as satisfactory when a number of conditions are met:

- Signal from ABA system

- Signal from AIA system

- Signal from PIR

- Signal from activation contact

- Signal from door contact

- Signal from microswitch mounted on hose connector shut-off valve

All types of override signals are subject to a number of detailed requirements for them to be considered satisfactory. These detailed requirements are set out in the DBI note here: DBI Note on Signal Sources

DanTaet leak protection systems support all of the above override signals. We always recommend signal from ABA as the primary solution.

The building owner is, as a rule, responsible for the building’s fire installation, which is why we, of course, always recommend that the building owner contemplates the consequences of installing leak protection systems if the installation contains fire hose reels.

Contact us for more information.